Introducing the XTR series of encapsulation machines.

Powerful. Seamless. Controlled.

XTRa everything.

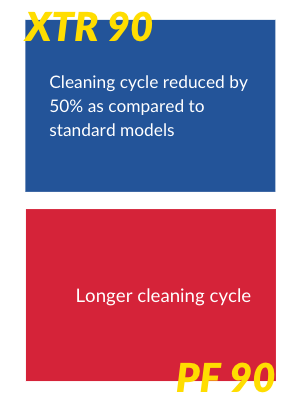

The XTR's clever design delivers exceptional production density with complete in-process control, precision and dosing flexibility at 60% less footprint than standard machines. You can encapsulate powder, pellets, tablets, micro tablets, liquids, capsules or soft gel capsules in capsules. No additional machinery. Just exceptional efficiency. Better yields. Impressive savings.

Our core features:

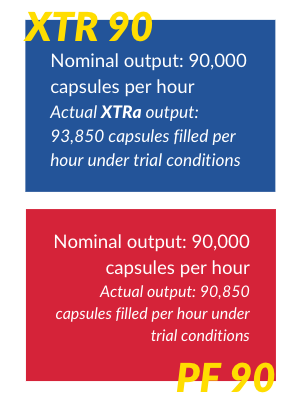

25,000 to 200,000 capsules per hour

Fills capsules from 000 to 5 in a 10 - 12 station operation

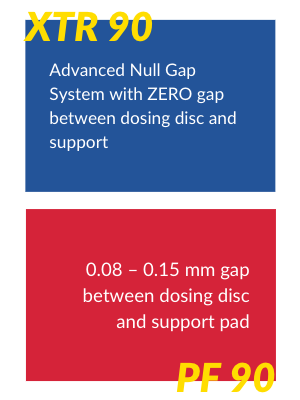

Null Gap System for accurate fills with a weight variation of +/-1%

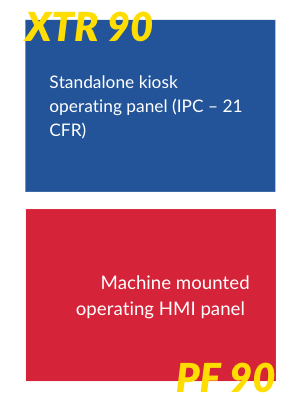

21 CFR and SCADA inbuilt

Country-specific CE certified

cGMP compliant

We're not done... there's more

DOUBLE LINED OIL SEALS

FDA COMPLIANT PEEK BUSHES

SERVO DRIVE INDEXER

TINUM-n COATED TAMPING PINS

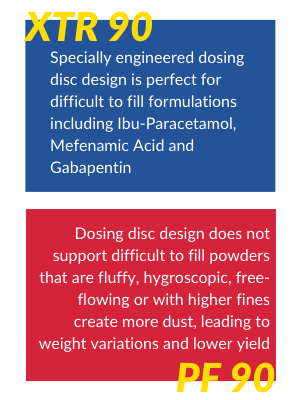

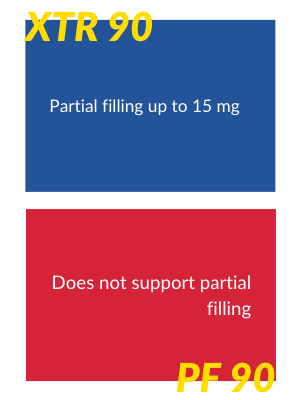

POWDER ASSEMBLY

DIGITAL GAUGES

POWERFUL LED INDICATORS

TWO WAY MOUNT + WHEEL MECHANISM

PROXIMITY SENSORS

Flawless engineering. Effortless encapsulation.

"*" indicates required fields

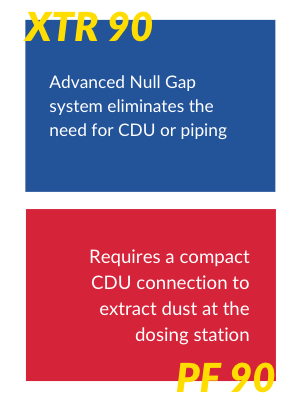

Null Gap System

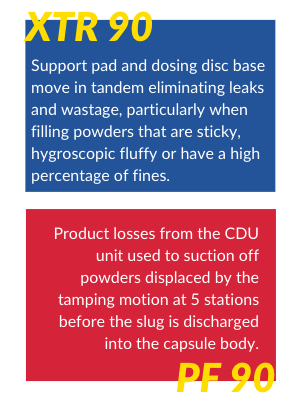

The XTR's advanced NGS (Null Gap System) tamping technology guarantees accurate capsule fills with weight variation under +/- 1% and improves yield by up to 10% making it best in class even for hard to encapsulate products. Yield improves up to 10%, rejections are minimal and formation powder is maximised reducing variable costs significantly.

Featuring TINUM-n

The XTR's tamping pins are hard-coated with TINUM-n using a state-of-the-art physical vapour deposition process. This special application pharma-grade coating has inherent anti-sticking properties and superior wear and corrosion resistance, particularly for pharmaceutical applications.

Why settle for standard when you can have XTRa?

>

>

>

>

>

>

>

>

>

>

Beyond business as usual

We’re committed to understanding every nuance of your needs and harnessing all of our creative energy to innovate for you so you can achieve your business goals.

Integration

Our design and engineering experts will work with you to understand your manufacturing ecosystem and how the XTR fits in before making recommendations.

Quality

Savings

Our client advisors will help you improve the efficiency of your encapsulation processes so you can increase yield, reduce change-over time, reduce cost and increase productivity.

The might of 3

With the geographical reach of our partners Fabtech and Parle, we can support you with the highest service standards no matter where you are in the world. We're always a phone call away.

For us, every innovation is an opportunity to disrupt an industry, so you benefit.

Let's talk about your encapsulation needs

"*" indicates required fields